Silk screen printing, also known as screen printing or serigraphy, is a versatile and popular method for creating custom designs on shirts and other textiles. This age-old technique involves transferring ink through a mesh screen onto the shirt, resulting in vibrant and durable prints. In this comprehensive guide, we from the platform of silk screen printing in Dallas will delve into the intricate process of silk screen printing on shirts, covering everything from the history of the technique to step-by-step instructions for creating your own prints. Whether you’re a beginner or an experienced printer, this guide will provide you with the knowledge and skills needed to master silk screen printing on shirts.

Understanding Silk Screen Printing:

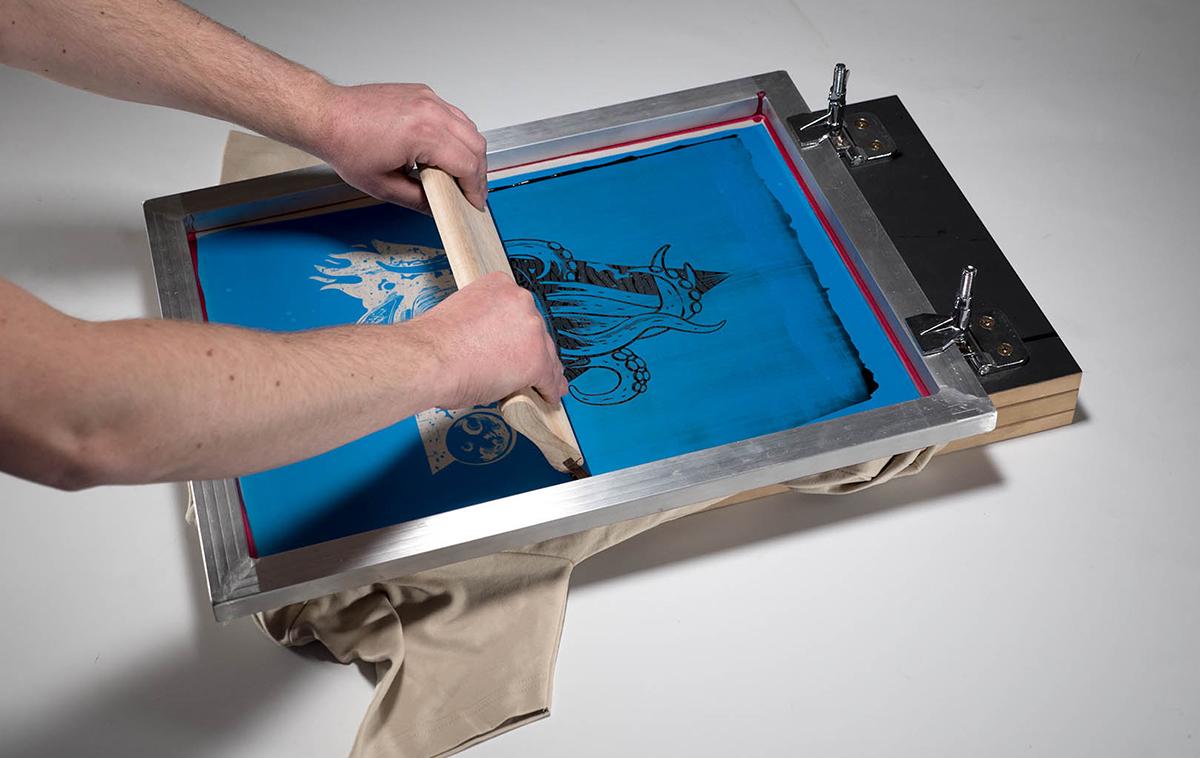

- Silk screen printing is a stencil-based printing technique that dates back centuries. Traditionally, silk was used as the mesh material for the screen, hence the name. However, modern screens are typically made from polyester or nylon. The design is transferred onto the shirt by making a stencil on the screen and then forcing ink through the mesh using a squeegee.

History of Silk Screen Printing:

- Silk screen printing has a rich history that spans cultures and civilizations. The technique is believed to have originated in China during the Song Dynasty (960-1279 AD), where silk fabric was used to create stencils for printing patterns onto clothing and other textiles. It later spread to Japan and other parts of Asia before gaining popularity in Europe and eventually the rest of the world.

Equipment and Materials:

- To perform silk screen printing on shirts, you’ll need the following equipment and materials:

- Screen: A mesh screen made from polyester or nylon, stretched tightly over a frame.

- Emulsion: In order to make the stencil, a light-sensitive coating is put on the screen.

- Squeegee: A tool used to force ink through the mesh onto the shirt.

- Ink: Specialized screen printing ink formulated for use on textiles.

- Shirt: A blank shirt made of cotton, polyester, or a blend of fabrics.

Preparing the Screen:

- The first step in silk screen printing is preparing the screen. This involves coating the screen with a light-sensitive emulsion and allowing it to dry in a darkroom. Once dry, the emulsion-covered screen is exposed to UV light through a stencil, hardening the emulsion in the exposed areas and leaving it soft and washable in the unexposed areas.

Creating the Stencil:

- With the screen prepared, the next step is to create the stencil for the design. This can be done by hand or with the help of a computer and printer. The stencil is then adhered to the screen using a light-sensitive tape or adhesive.

Printing Process:

- Once the stencil is in place, the screen is ready for printing. Ink is applied to one end of the screen, and a squeegee is used to pull the ink across the screen, forcing it through the mesh and onto the shirt below. Multiple passes may be required to achieve the desired coverage and intensity of color.

Curing the Ink:

- For long-lasting and wash-fast prints, it’s important to let the ink dry after printing. This is typically done by passing the printed shirts through a conveyor dryer, where they are exposed to high temperatures for a specific amount of time. The ink is permanently attached to the cloth fibers after it has cured.

Quality Control and Finishing:

- Throughout the printing process, operators monitor the print quality and make adjustments as needed to ensure consistent results. We verify every printed shirt carefully to make sure there are no mistakes, misprints, or discrepancies. The last step is to fold, label, and package the shirts for either distribution or retail sale.

Conclusion:

Silk screen printing on shirts is a time-honored technique that offers endless possibilities for creating custom designs with vibrant colors and durable prints. By following the step-by-step process outlined in this guide, you can master the art of silk screen printing and create stunning shirts that showcase your creativity and style. Whether you’re printing shirts for personal use, promotional purposes, or retail sale, silk screen printing offers a versatile and effective method for bringing your designs to life.